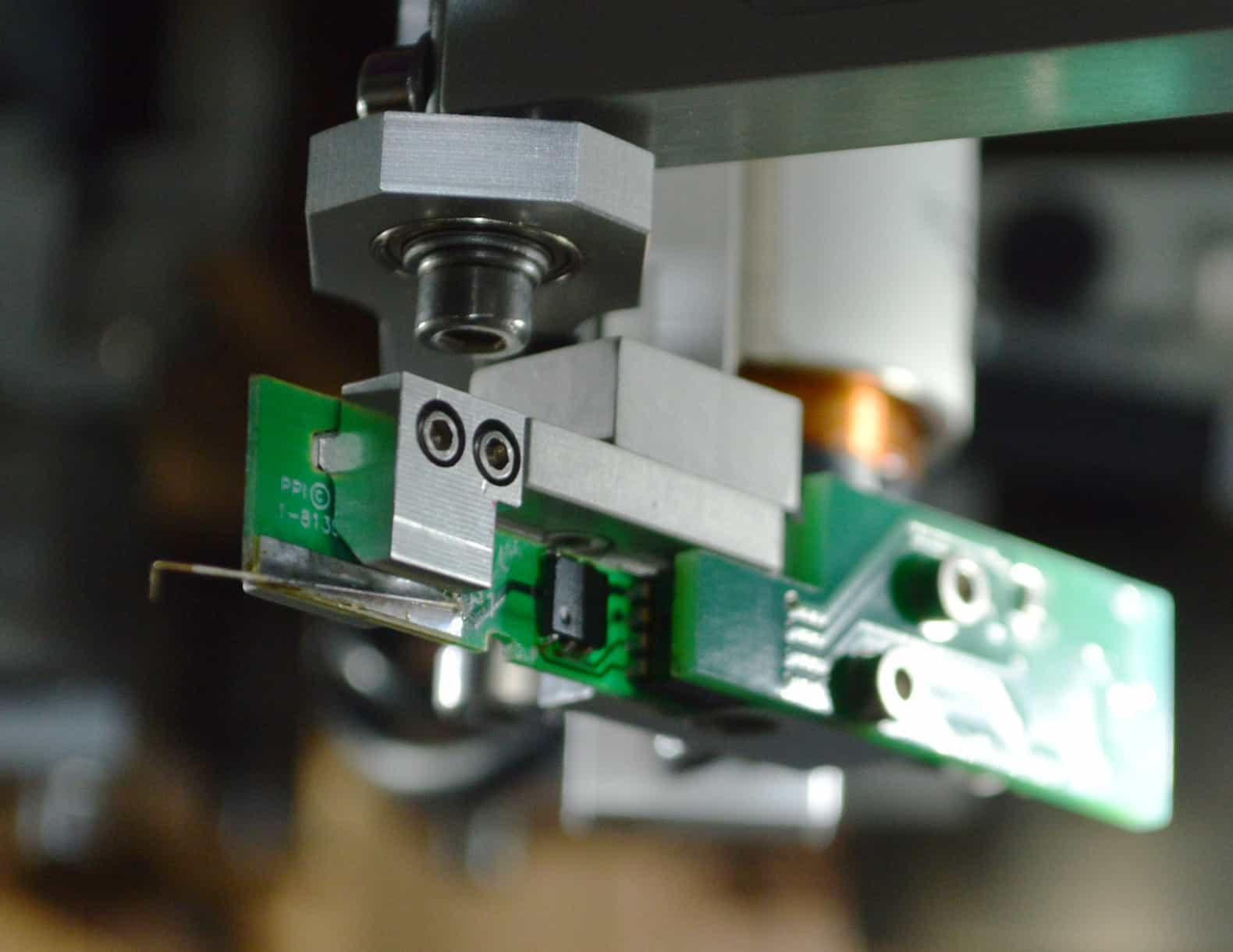

Next Generation Probe Card Based Resistor Trimming Systems

Over forty years ago electronics manufacturers developed the process of using a laser to adjust operating parameters of an electronic component or circuit by reducing the amount of resistor material. Early designs used probe cards for their testing method as they were an excellent solution to high volume production applications.