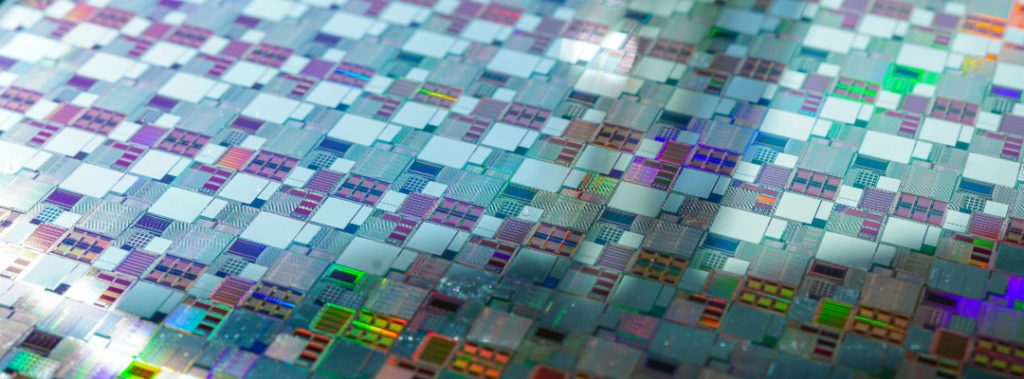

RapiTrim Semiconductor Wafer Trimming Systems

SYSTEMS

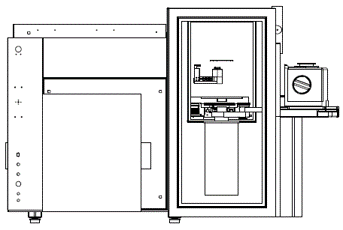

RapiTrim-S

- Semiconductor Wafer Trimming System

- IR Laser Options (1060 nm or 1300 nm)

- Advanced high-performance prober

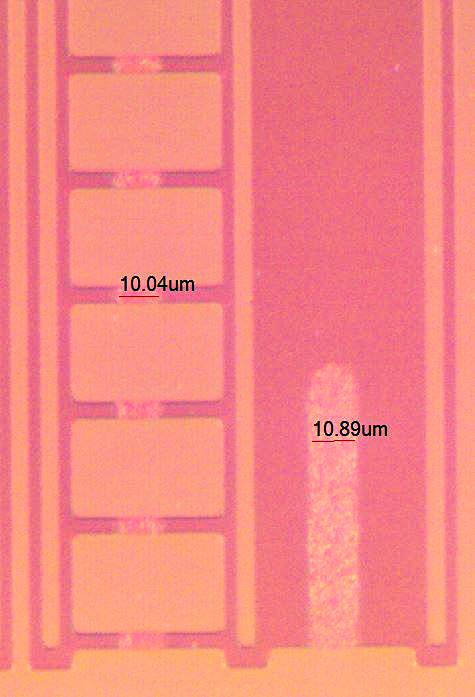

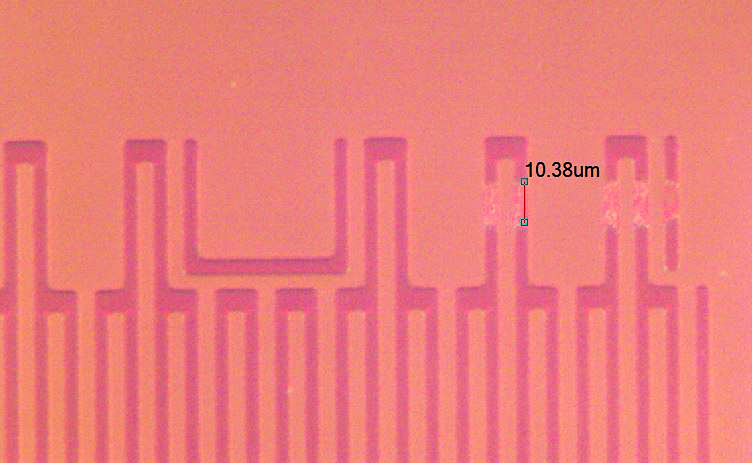

- Spot Size 6-12 µm

- Broad ATE compatibility

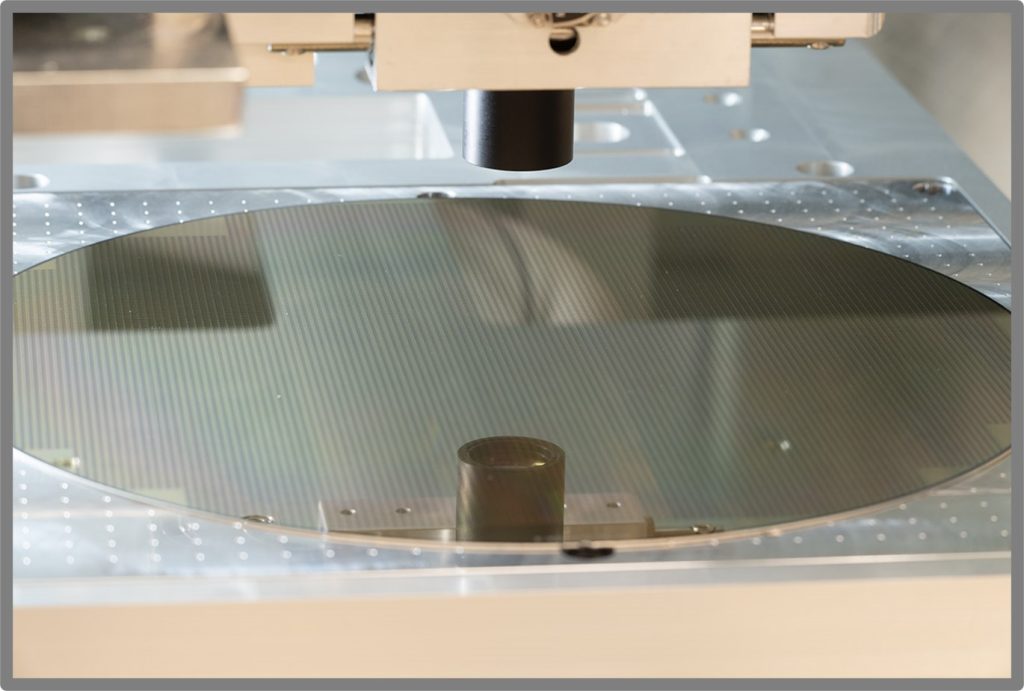

High speed semiconductor wafer trimmer.

The next generation RapiTrim wafer resistor trimmer is a full turnkey system with IR laser, producing spot sizes of 6 to 12 um. It is designed for high throughput optimization of linear and mixed-signal IC devices through the integration of laser trimming, probing and testing. ProSys trimming software allows rapid job setup and new process development.

Features include:

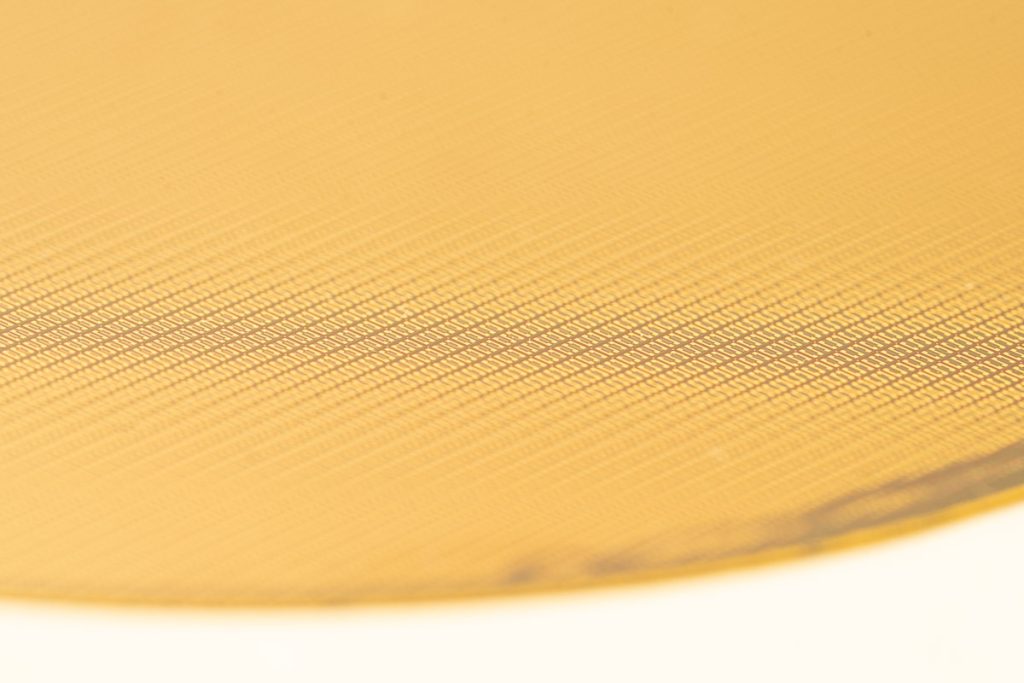

- Designed for trimming on semiconductor wafers.

- Compatible with industry standard probe cards and integration with modern automatic testing equipment.

- Advanced beam positioning and pulse control for improved process quality, accuracy and trim speed.

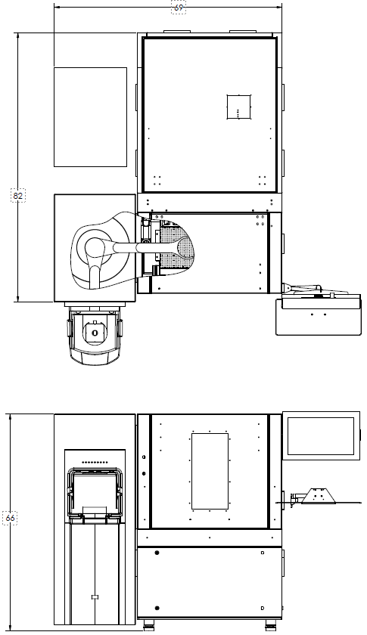

- 300×300 mm vacuum chuck, options include non-ferrous / non-conductive and thermal control

- Automatic run-time calibration for optimum process integrity

- Turnkey customized solutions for both full wafer and singulated die, with and without automated part handling.

- PPI Systems will provide assistance translating legacy programming to RapiTrim wafer trimmers.

Best-in-class Mechanical and Optical Performance

Advanced Beam Positioner

- Configured for desired spot size (typically 6-12µm) and laser wavelength (1060nm or 1300nm)

Frictionless actuators and digital optical feedback provide superior dynamic performance and precision trajectory control

Sub-micron accuracy with through-lens vision and laser edge detection of die alignment features

Real-time cut control using integrated measurement system or external tester signaling

- Laser optics including vision are mounted to an independent Z stage that can focus on the wafer when not in contact with the probes. The wafer moves up in Z to contact probes during processing.

Probe Card Alignment and Cleaning

- Compatible with industry standard probe cards and custom test fixtures

- Probe needle best-fit positions are calibrated using cameras mounted under the chuck.

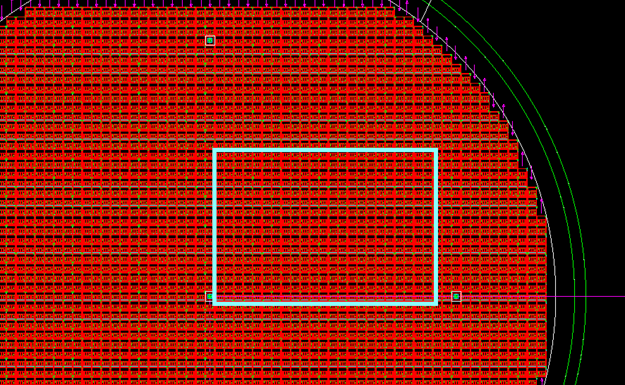

- Wafer orientation is determined using the vision system. Probe positioning and cut orientation are corrected based on this alignment.

- Wafer surface Z position is determined using one or more points (surface map) during alignment. Z position is adjusted during stepping at each die based on this map.

- Probe cleaning / scrubbing routines are parameterized and can be run manually from the UI and automatically during the wafer trim process.

Compatible with Industry Standard Test Equipment

- System software and trim controller interface to mixed signal external testers through discrete high-speed signaling as well as data communications for setup, trim and test program control and synchronization

- Trim controller interfaces to industry standard testers and/or discrete external instrumentation for passive and active trim operations

- Standard probe switching functions to access the DUTs

- Integrated signal routing switch provides functionality for active trim, external test equipment, and specialized measurement applications

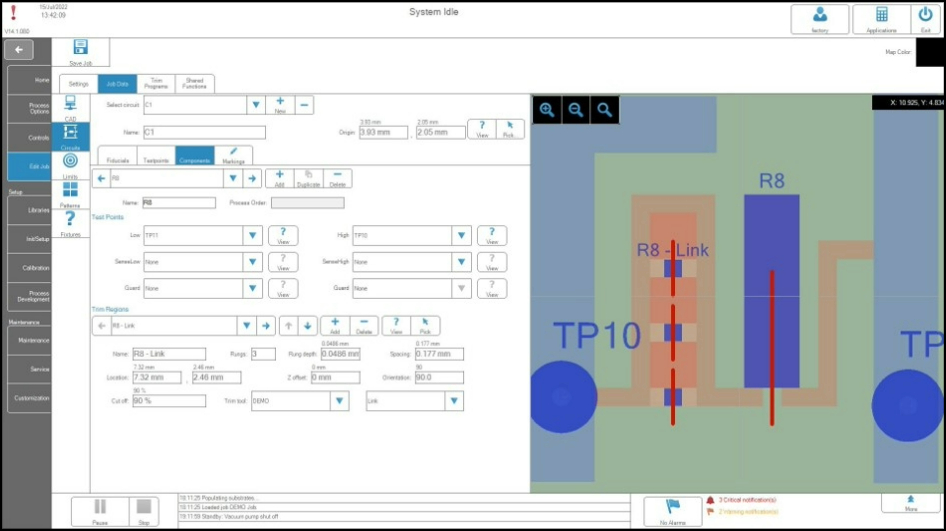

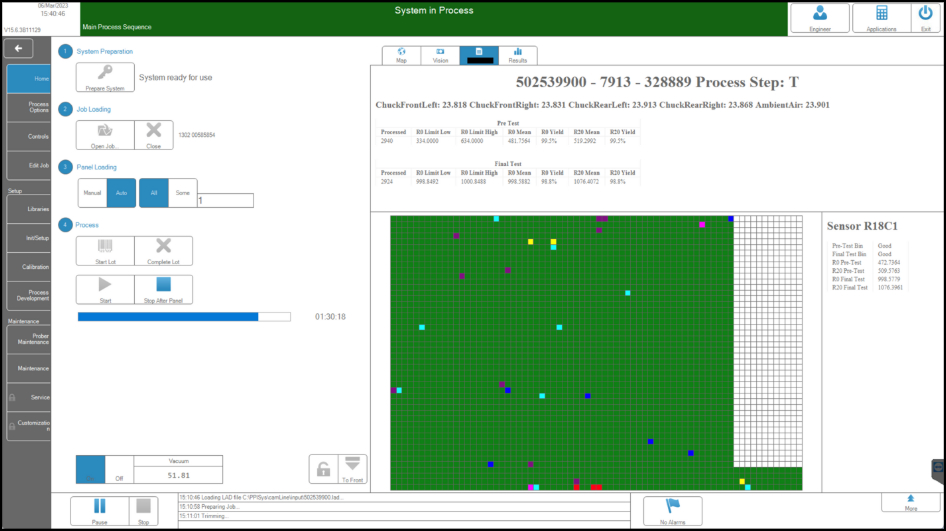

Intuitive Graphical Job Setup with Real-time Trim Logic Scripting with ProSys Resistor Trimming Software

An intuitive graphical user interface that offers unmatched ease of use for both operators and process engineers. Easily access all system setup and calibration controls, job and process settings, vision and process map, status and diagnostic information. Trimmer Logic allows the system software and the trim controller to interface with mixed signal external testers.

- Simplified Job Setup with Real-time Trim Logic Scripting

Simple user controls with customizable data and progress displays

- Process map – visualize all job features in map or camera overlays. Clearly see at a glance what and where the process is, in real time.

- Fully automatic run-time calibration activates when it needs to, ensuring process stability and accuracy.

- Real-time system monitoring for process integrity

- Touchscreen support for all Operator interaction

Automation

PPI Systems resistor trimming systems offer easy integration with industry standard wafer loader / unloader options.

- ADO load port, SEMI compliant

- 6”, 8” and 12” wafer compatibility

- Bare wafer or film frame

- FOUP, SMIF, open cassette with adapters

- OCR and ID Matrix reader

- Pre-aligner

- Vacuum / edge grip end effectors