RapiTrim Resistor Trimming Systems Add More Complexity to Testing Options

RapiTrim Resistor Trimming Systems Add More Complexity to Testing Options

(Ottawa, ON) Jan. 2021 As circuit density and complexity continues to increase, testing options have become a critical component of laser resistor trimmer design. Older laser trimming systems were based on in-circuit testing (ICT) through probe cards, however as needs change many production facilities require unique options, or in many cases a combination of solutions. These can include flying probes, probe cards, pogo pins or custom testing options, all of which are available on RapiTrim systems.

The RapiTrim laser resistor trimming system is available as a turn-key or custom solution dependent of each specific customer need. Current customer requests include active trim systems with unique side electrical connections in combination with pogo pin testing on the bottom surface of the substrate as well as customized flying probe and probe card setups. For the last 10 years PPI Systems has worked diligently to provide market leading testing options for their diverse set of worldwide customers.

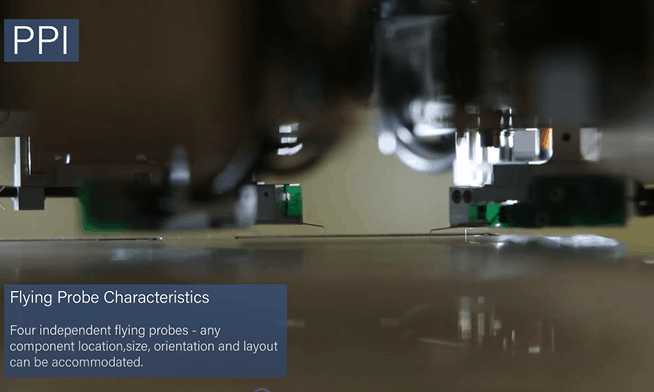

Flying Probe Operation

Standard models incorporating PPI's proprietary high-speed flying probe technology eliminate probe cards and their inherent limitations, providing many advantages.

“After nearly 20 years of laser system development, RapiTrim systems provide world-leading testing customization features in both hardware and software.” states Anton Kitai, President of PPI Systems. “As we continue to produce advanced laser trimming testing today, we’re planning for next generation options to meet future laser resistor trimming needs.”

PPI Systems Inc., located in Ottawa, Canada, is a leading supplier of laser material processing and test systems. The company provides a broad range of turn-key solutions to the interconnect and electronic component market for via drilling, circuit processing, resistor trimming, and high precision micro-machining.

Request for Information

Laser Resistor Trimming Systems

Laser Via Drilling Systems